INFRARED TECHNOLOGY

A Non Dispersive Infrared (NDIR) gas sensor working principle is based on the property of certain molecules to absorb light at specific wavelengths (or “color”) that are characteristic of their molecular structure. The absorption characteristics are defined as molecular vibrational energies associated with stretching, bending or rotations and depends upon the molecular structure of the gas.

For IR energy to be absorbed, that is for vibrational energy to be transferred to the molecules, the frequency must match the frequency of the mode of vibration. Thus, specific molecules absorb IR radiation at precise frequencies and each gas has a unique and well defined light absorption curve in the infrared spectrum.

When IR radiation passes through a volume containing a specific gas, only those frequencies matching the vibration mode are absorbed, while the rest of the light is transmitted without interference. For this reason, the presence of a particular gas gives rise to characteristic absorption bands.

The Beer-Lambert Law, a basic law of physics, relates the attenuation of light to the properties of the material (gas, in our case) through which the light is travelling. According to it, the strength of an NDIR sensor signal is proportional to:

- the intensity of the beam of IR light;

- the specific absorbance characteristics of the molecules of the gas being measured;

- the length of the optical path (the distance traveled by the light through the volume);

- the actual concentration of the gas being measured.

By knowing item 1, 2 and 3, we can determine item 4, that is the actual concentration.

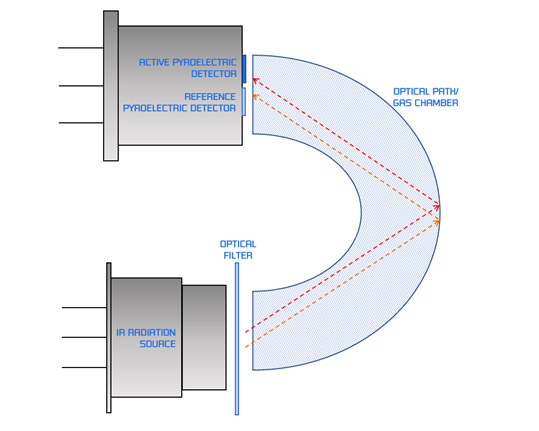

Infrared gas sensors employ a dual wavelength technique, using an IR energy source aimed at two pyroelectric detectors, each sensitive to different ranges of wavelengths in the spectrum’s infrared portion.

A Pyroelectric detector is an infrared sensitive optoelectronic component which are specifically used for detecting electromagnetic radiation in a wavelength range from 2 to 14 µm.

The Active detector is sensitive in the range of absorption of the target gas, while the Reference detector wavelength bands are chosen in a region of the IR spectrum where there is minimal absorbance of the gas of interest.

The differential absorption technique, where the target gas is always monitored with respect to a reference measurement, attenuates the effect of background distortions due to response to other gases, source aging or optical surface contamination. Both Active and Reference channels are equally attenuated when contaminants are present within the IR beam or when the source decays over time.

Infrared gas sensing offers many advantages over other traditional technologies:

- It can operate within oxygen-deficient or oxygen-enriched areas, a big plus for combustible gas detection.

- Is very selective for the target gas and has very low cross-sensitivity with other gases.

- Is corrosion-resistant and it cannot be poisoned.

- Is fail-safe, as events such as beam block or failed detectors or sources are revealed (read our article)

- Requires no routine calibration, as aging effects are limited by differential absorption technique.