IREF PRO vs IREF LITE – which is right for me?

NET offers the most comprehensive range of NDIR sensors on the market for refrigerant gas detection. Across different platforms and technologies, we can provide solutions for over 40 different common refrigerants.

Our two main platforms for refrigerants are IREF PRO and IREF LITE. Users are often asking us what platform better fits their application needs – so here’s a brief checklist which will help you making the right choice.

1. PRICE

A strong differentiator between PRO and LITE is the price, with the latter costing about half the price of the former. The reasons for this price difference are the built (see item 9) and the fact the PRO implements a more selective – and expensive – IR source, allowing better overall detection performances.

The IREF LITE is generally a good fit for commercial and light industrial applications, while for more demanding services the PRO is normally preferred.

2. DETECTED GASES

IREF PRO has been released in 2013, while IREF LITE debuted in 2019. This means we have been working on the PRO for over 10 years and we had time to develop more gases on it. We also had time to determine cross factors for several more gases on this platform (see item 6). As a result, the gas list of IREF PRO is indeed impressive. See the relevant product page for the complete list.

IREF LITE was initially designed to detect A2L gases in flammable range. Although we are progressively implementing more gases and ranges on this platform as well, the LITE gas list is not as deep as the PRO’s. See the product page to check what gases are available.

3. DETECTION RANGE

The more selective IR source implemented by the IREF PRO allows detection of most gases in a 0-2000ppm range, in some cases even 0-1000ppm.

On the other hand, the IREF LITE allows detection in a 0-5000ppm range and, in the case of R-32 and R-410a, in a 0-10.000ppm range.

Both platforms have of course no problems in detecting the gases in their flammable ranges, which corresponds to much higher concentrations.

4. DETECTION ACCURACY

That’s another area where the superior IR source of the IREF PRO gives it an advantage. The typical accuracies of the two platforms are given here below:

IREF PRO:

- ±1% of FS range for readings below 25% of range

- ±2% of FS range for readings below 50% of range

- ±5% of FS range above 50% of range

IREF LITE:

- ±5% of FS range for readings below 50% of range

- ±7% of FS range above 50% of range

FS = Full Scale

5. LOWER DETECTABLE LIMIT (LDL)

It is worth noting that our standard refrigerant sensors come with a dead band (or “squelch”) feature which suppress readings below 3% of F.S. This avoids continuous positive signal fluctuations due to environmental changes. When the detection does not require extremely low LDLs, we recommend keeping this feature activated at all times.

When instead LDL is at an absolute premium, the IREF PRO is definitely the right option. By disabling the dead band effect, the minimum measured concentration of the target gas that can be reported with confidence is at about 1% of the sensor F.S. – that is concentrations as low as 10÷20ppm.

On the other hand, the IREF LITE’s LDL should be considered 3% of the sensor F.S. – that is 150ppm for sensors with a 5000ppm F.S. and 300ppm for sensors with a 10.000ppm F.S.

6. AVAILABILITY OF CROSS FACTORS

As mentioned in item 2, NET has determined cross factors allowing specific IREF PRO sensors (notably, R-125, R-134a, R-32, R-507, R-1234yf and R-1234ze sensors) to be used when detecting multiple other gases, including some gases for which a dedicated sensor is not available yet from NET. Please refer to the relevant manual for more information.

If you are planning to exploit this feature, then the IREF PRO is certainly your choice as the same factors are not available yet for the IREF LITE (although this is in our R&D plans for the near future).

7. TEMPERATURE RANGE

The IREF PRO has been designed for critical services and demanding applications and features a standard temperature range of -20 to +50°C. This can be extended to -40 to +60°C with a special calibration cycle (MOQ and different prices may apply – if you are interested, please contact us for more details).

The IREF LITE, on the other hand, has been designed for commercial and light industrial applications and the temperature range is -10 to +50°C.

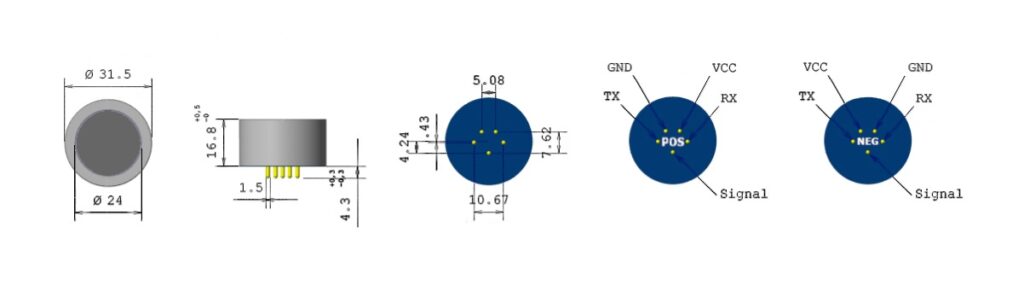

8. PINOUT

All NET NDIR sensor feature a standard industrial footprint. But while the IREF PRO is available with both Negative and Positive configuration, the IREF LITE is only available in Negative. See the diagram below for details

9. BUILT

IREF PRO shares the same built of our renowned IRNET PRO industrial sensors. This means a strong stainless-steel housing and double filter (PTFE underneath, plus metal mesh outside) protecting the optical path and components – ensuring ultimate protection even under the most extreme and aggressive environments.

IREF LITE is instead made of an aluminum housing with a single PTFE filter protecting the optical parts, reflecting the less demanding environments for which it is designed and allowing a lower price.